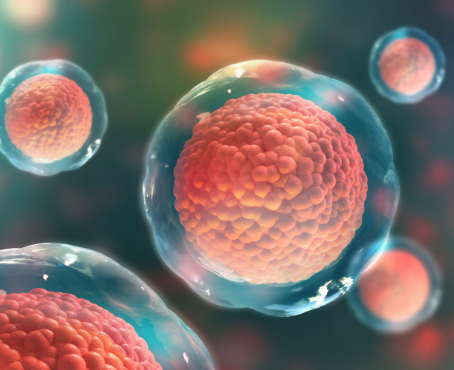

Our lead product, Lomecel-B, consists of human allogeneic bone-marrow derived MSCs as the active ingredient.

These cells undergo cultured-expansion using proprietary processes, and are then formulated, packaged and stored frozen (cryopreserved) until shortly before use. Fresh bone marrow is procured from established, licensed U.S.-based third-party tissue suppliers, which harvest the tissue from young, healthy consenting donors. Lomecel-B is produced using techniques that FDA has reviewed and authorized as part of our INDs.

We have assembled a team of experts and proprietary technologies that enable us to take a systematic approach to rapidly develop improved cell therapies. We believe having established manufacturing capabilities and operations within the U.S. early in the development of our product candidates is a competitive advantage. Over time, we expect to expand regional manufacturing capacity and potentially add external supply nodes to meet projected product requirements for commercialization.

The manufacture and delivery of cell therapy products to patients involves complex, integrated processes. Commercial success in this area requires manufacturing processes that are reliable, scalable, and economical. We have and will continue to devote significant resources to process development and manufacturing to optimize process robustness and success rates in developing Lomecel-B and other potential product candidates, as well as to reduce per-unit manufacturing costs and enable us to quickly achieve regional and global scale production upon regulatory approval for any of our product candidates.

We currently operate a manufacturing site in Miami, FL, which supplies Lomecel-B for our clinical trials. We also intend to expand the manufacturing capacities in the U.S. and potentially Japan or other regions in Asia for commercialization at both a regional and global scale upon regulatory approvals.

Longeveron’s corporate headquarters and manufacturing facilities are located in the Converge Miami Building in Miami, Florida. This state-of-the-art GMP facility consists of 3,000 ft2 of cleanroom space containing 8 ISO 7 cleanrooms and ancillary areas as well as 1,150 ft2 of process development, quality control and warehousing space. All products are manufactured and released based on FDA guidance to include 21 CFR 210, 211, 606 and 610.

Click here to replay our KOL event, which was held on August 16, 2023, featuring Sunjay Kaushal, MD, PhD and Ram Kumar Subramanyan, MD, PhD, discussing the potential for Medicinal Signaling Cells (MSCs), such as those making up Longeveron’s Lomecel-B™ injection, to improve the outcome for Hypoplastic Left Heart Syndrome (HLHS) patients.

Click Here to Watch the Replay